Evaluating Starch Manufacturers: Key Performance Indicators for 2025

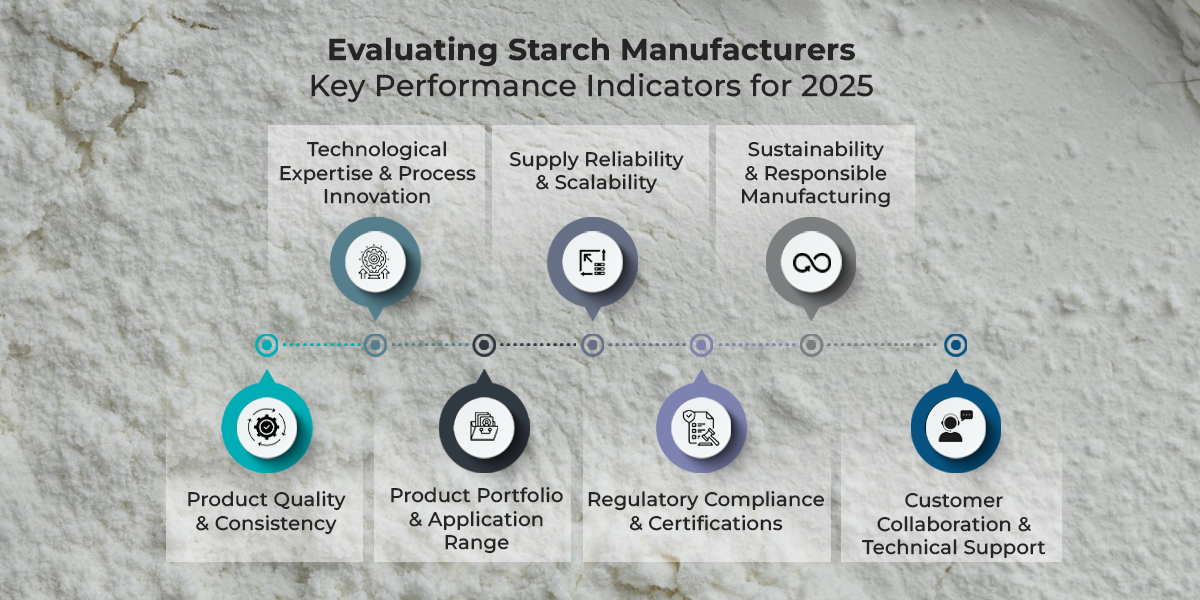

As demand for starch continues to rise across food, pharma, textile, paper, and industrial sectors, the importance of selecting the right starch manufacturers has never been greater. In 2025, buyers are not only seeking reliable suppliers, but they are also evaluating producers on quality assurance, consistency, technological capabilities, and sustainability practices.

For companies that depend on starch as a critical input, understanding the right performance indicators helps ensure long-term value and product reliability.

Understanding the Role of Starch Manufacturers

Starch is a foundational ingredient across multiple industries, valued for its thickening, stabilizing, binding, and texturizing properties. From corn starch in India used in food and pharmaceutical formulations to customized variants developed for industrial use, the product’s quality and performance directly depend on the manufacturer’s process control and expertise.

Modern starch manufacturers operate in an environment where quality, efficiency, and customization define competitiveness. Evaluating these aspects helps businesses identify suppliers capable of delivering consistent results at scale.

1. Product Quality and Consistency

Quality remains the foremost indicator of a reliable starch producer. Whether it is native corn starch or a specialized modified variant, consistency in granule size, moisture content, and viscosity determines how effectively starch performs in end applications.

Key evaluation points include:

- Purity levels: High-grade starch should have minimal impurities and uniform composition.

- Functional performance: The ability to maintain viscosity, texture, and stability across production batches.

- Testing and certification: Compliance with national and international quality standards.

Manufacturers that invest in modern quality-control systems and standardized testing protocols ensure repeatable performance, a critical factor for sectors like food and pharma, where even minor variation can impact product outcomes.

2. Technological Expertise and Process Innovation

The starch industry may be built on long-established principles, but processing technologies continue to evolve. The capability to adopt modern techniques for refining, drying, and modifying differentiates advanced producers from conventional ones.

Manufactures of specialty starches such as oxidized, cationic, or acid-modified varieties require precise process control and technical understanding. These modifications adjust key attributes, such as viscosity, adhesion, and film formation, to suit specific industrial needs like paper coating, textile sizing, or adhesive formulations.

Evaluating a starch manufacturer’s technological investment reveals their ability to deliver customized solutions and maintain consistent performance under varying operational conditions.

3. Product Portfolio and Application Range

In 2025, end-users will increasingly prefer suppliers offering a broad portfolio of starches tailored to different industries. Leading starch manufacturers provide:

- Food-grade starch for texture and stability enhancement.

- Pharma-grade starch for binding and controlled release in tablet formulations.

- Industrial starches such as paper and textile-grade starch for sizing, finishing, and coating.

- Specialty and modified starches made to order for unique processing requirements.

A diversified product portfolio demonstrates capability, experience, and adaptability - three attributes that buyers should prioritize when assessing potential suppliers.

4. Supply Reliability and Scalability

With global supply chains facing fluctuations in raw material availability, dependable sourcing has become a vital consideration. A high-quality corn starch supplier must ensure uninterrupted supply, efficient logistics, and responsive customer service.

Key performance metrics include:

- Procurement stability: Consistent access to quality maize and raw materials.

- Processing capacity: The ability to handle large-scale production without compromising quality.

- Lead time and delivery efficiency: Reliable scheduling and order fulfillment.

Bluecraft Agro, for instance, maintains robust procurement networks and integrated production facilities to ensure a steady supply and quick response to client requirements across India and global markets.

5. Regulatory Compliance and Certifications

Industries such as food, pharma, and personal care require adherence to stringent safety and regulatory standards. Evaluating certifications helps ensure compliance and product integrity.

Buyers should verify credentials such as:

- ISO certifications for quality management.

- Food safety and GMP compliance for consumable applications.

- Environmental and workplace safety standards to ensure ethical production practices.

Certified operations signal accountability and transparency key traits of a credible starch manufacturer.

6. Sustainability and Responsible Manufacturing

While starch itself is a commodity derived from agricultural sources, manufacturers are increasingly adopting sustainable practices to minimize environmental impact. For example, efficient water management, waste recycling, and energy optimization in corn starch production reflect a company’s commitment to responsible operations.

It is important to note that sustainability applies to manufacturing processes, not to starch as a material. The focus should be on operational efficiency and responsible resource use rather than portraying starch itself as a sustainable product.

7. Customer Collaboration and Technical Support

Today’s partnerships go beyond supply contracts. The best starch manufacturers collaborate with clients to understand process challenges, test product performance, and recommend the most suitable starch solutions.

Manufacturers that provide technical support and R&D assistance help customers improve product outcomes, whether through optimizing viscosity, enhancing texture, or achieving better process stability.

Bluecraft Agro: Benchmarking Quality and Reliability

As one of India’s trusted producers of corn starch and its derivatives, specialty starches, and modified starches, Bluecraft Agro sets the benchmark for quality, consistency, and customer-centric operations. With advanced production systems, rigorous testing protocols, and application-specific expertise, the company delivers starch products that meet both functional and performance expectations.

Whether you require a high-quality corn starch supplier for food and pharma or a reliable partner that manufactures specialty and modified starches for specific applications, Bluecraft Agro offers the precision and dependability needed for long-term success.

Connect with Bluecraft Agro

Partner with a leading starch manufacturer from India that combines technical expertise with process reliability.

Email: marketing@bluecraftagro.com

Call: 02717 454547