Excess energy in plants is stored as glucose in the roots, stems and leaves of plants. The glucose is converted into starch by enzymes in the form of tiny granules. The starch is then processed and applied in different industries.

Maize has the highest starch content and is the leading starch crop for industries producing agro-based starches.

|

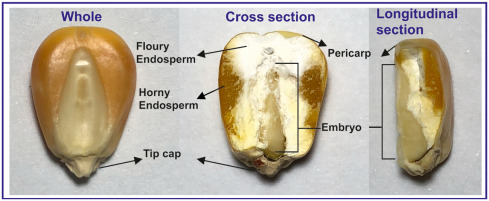

Corn, as the major starch source, provides over 85% of the starch produced all over the world. Corn kernels consist of 61%–78% starch on a dry basis (d.b.), non-starch polysaccharides (about 10%, d.b.), protein (6%–12%, d.b.), and lipids (3%–6%, d.b.) |

Maize starch is produced by extracting a fine powder from the starchy centre of maize kernels known as the endosperm. In the process of extracting starch, all the layers- seed coat (bran), tip cap, and seed germ surrounding the kernel are removed. These layers produce nutritious by-products like maize bran, maize germ, maize gluten, maize steep liquor, etc.

“Maize wet-milling” process is employed to procure starch from the crop. It separates the kernel through a series of processes using water.

Procedure:

-

Cleaning

Foremost, the crop is cleaned before it goes through any processing. The non-essential components like cob pieces, foreign seeds, leaves and dirt are filtered out and the cleaned maize is then analysed.

-

Steeping

The maize is soaked in water along with sulphur dioxide and lactic acid. Lactic acid enables the endosperm to break and separate the starch. This entire process is known as steeping. It helps the endosperm proteins to solubilize and diffuse. The steep water is then drained out and concentrated using evaporators.

|

The clean corn is steeped in large tanks with water at 125-130˚F containing lactic acid and sulphur dioxide for nearly 40 hours. |

-

Germ Recovery

The germ is separated from the other parts to avoid oil contamination. Slow grinding occurs through attrition mills and ensures germ removal. Water is added to the ground material to make a thick paste of the kernels and whole germ. This leads the germ particles to float as they are less dense due to the presence of oil. The mixture then passes through hydro cyclones with an under and overflow.

-

Fibre Recovery

The underflow’s proteins, fibres and starch are then finely ground and screened through multiple grind mills and pressure-fed screens. This screening enables the starch and proteins to pass through. Only the fibres separate, being termed as maize gluten feed.

-

Protein Recovery

Like fibre recovery, the proteins (mill starch) get filtered out in this process. Water is removed from the mill starch and centrifugal forces are applied to separate the starch and gluten. The starch stream has 90% starch and the gluten stream has 60% proteins. The heavier gluten is dewatered and the lighter gluten is thickened. The water from these processes is either removed or added to the steep water.

-

Starch Processing

Since the starch goes through multiple washing processes, it is obtained in a highly pure state. The water from each hydro cyclone stage is recycled to the previous one ensuring the maximum amount of starch being separated.

The starch is then dried for industrial utility.

In the wet-milling process, the by-products released in the form of maize bran, gluten, maize germ and steep liquor are rich in nutrients and contain carbs, proteins, oils and minerals. These are utilized in other industries, such as poultry and animal feed and edible oil production.